Ultrasonic Air Flow Management

Time of flight air flow management for mining & tunneling

Ultrasonic air flow management is critical for safe working conditions in underground mines and tunnels.

Ventilation is a regulatory requirement for underground mines and tunnels and proper management is critical to the health and safety of the workers. Ventilation technicians measure air flow so they can effectively control the supply and distribution of fresh air into the tunnel or mine. Ultrasonic air flow monitors provide continuous air flow measurement data so technicians can manage underground air flow.

How is air flow monitored in underground mining?

Generally, the mine’s ventilation technician will go underground periodically and take a reading with a pitot tube, anemometer, or other certified portable device which can be calibrated. The reading is then used to manually adjust the regulators to increase or decrease the flow requirements. Fixed airflow monitors are advantageous because they provide constant readings of airflow at various points throughout a mine or tunnel.

In underground mining, air flow is usually measured at strategic fresh air in-takes and also at the return or exhaust to improve the balance of inbound vs. outbound. The measurements validate that the air is moving at a sufficient velocity to deliver a proper refresh rate.

What is time-of-flight air flow measurement?

Time-of-flight uses dual sensor ultrasonic technology to measure the time it takes for sound to travel between two transducers. This information is used to calculate air velocity. The transducers are hardwired back to the controller which collects time-of-flight info between the two transducers and provides output data related to air velocity. The data is sent to a surface control room or SCADA through various available industrial protocols to inform ventilation decisions.

Time-of-flight transducers are maintenance free. They are completely impervious to temperature, pressure, humidity, and dust in harsh environments. Time-of-flight also allows for air velocity averaging and bi-directional measurement. Ultrasonic time of flight sensors are durable and long lasting since there are no moving parts. For these reasons, ultrasonic time of flight is the preferred air flow monitoring technology in underground mines and tunnels.

How are ultrasonic air flow sensors installed?

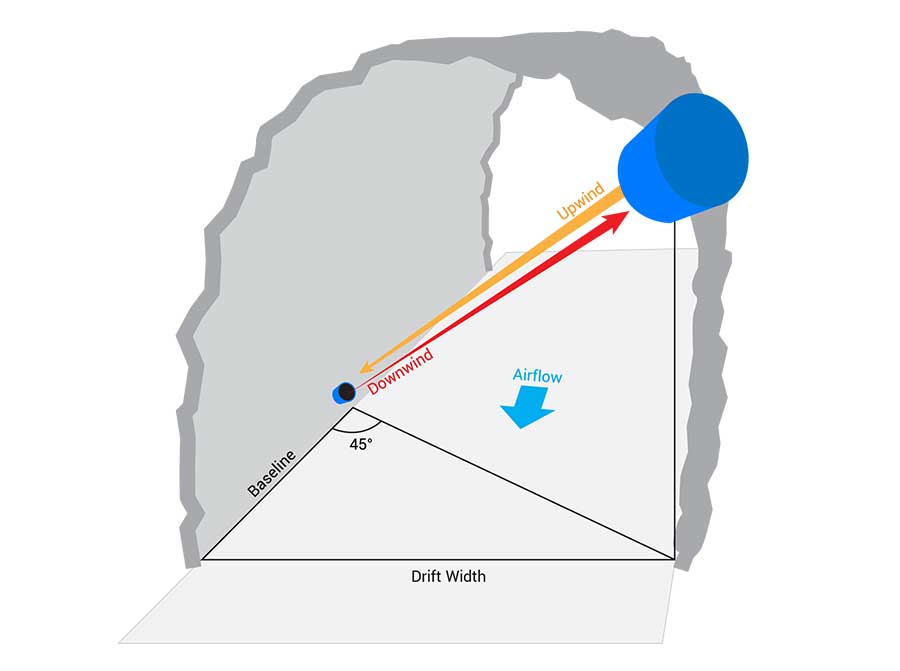

Ultrasonic air flow monitors use two time-of-flight transducers: one mounted at the top of the wall and the other mounted downstream near the bottom of the tunnel or drift. The distance downstream between the two transducers is called the baseline. It is recommended that the baseline be set such that the face-to-face vector between the two transducers is between 30-60 degrees to the airflow.

How do you calibrate an ultrasonic air flow monitor?

Ultrasonic time-of-flight airflow monitors do not require calibration, as there are no mechanical components used to measure velocity. However, ventilation technicians perform a 9 point survey using a certified portable device across the tunnel to confirm that data is within the expected tolerances of the flow rate.

Does ultrasonic technology work in turbulent applications?

Measuring turbulence is difficult and it has limitations. Ultrasonic time of flight technology can measure turbulence, where alternative technologies will struggle. Accutron has developed advanced algorithms and filters that allow for extremely repeatable results, providing the trends required for applications like fan control. Accutron technicians offer installation guidance for best results but generally, the fan application would be measured right at the fan, at either the suction or the discharge end.

Will improvements to ventilation management yield a return on investment for the mine?

It’s expensive to run an underground mine and air flow is a major operating expense, largely due to the electrical cost used to operate the fans. In hard rock mines, ventilation is a top five operational expense. Improved air flow management can yield a significant return on investment by reducing electricity bills and increasing operational efficiencies.

What is a Mine Air Quality Station?

The MAQS or Mine Air Quality Station is an all-in-one complete ventilation monitoring station which monitors air flow in tunnels, drifts, surface fans, and duct systems. The MAQS provides accurate and reliable field data on ultrasonic airflow, temperature, pressure, humidity, gas, dust and a wide range of airborne contaminants. It comes with multiple communication options and is designed to work with existing software and communications infrastructure.

The Accutron MAQS is a smart I/O indicating transmitter which uses time-of-flight technology to measure airflow. The MAQS is fully customizable and monitors a wide range of conditions.