Pinssar DPM

Diesel particulate monitor.

Pinssar DPM diesel particulate monitor provides continuous air monitoring of potentially deadly diesel exhaust emissions. Monitor levels of diesel particulate as they increase instead of knowing only after gravimetric sampling has been analyzed by the lab. Pinssar DPM allows your operations to protect your workers before they get exposed through management and controls.

- Continuous real-time readings every 5 minutes

- Ongoing validation/verification of mitigating controls

- Particle range is 0-800nm (70-370nm calibrated)

- Automatic zero drift compensation on every sample

- Integrate real-time information into your Ventsim model

Features

Real-Time Monitoring

Continuous real-time readings every 5 minutes for ongoing validation and verification of mitigation controls.

Easy Integration

The Pinssar DPM integrates with over 200 industrial protocol options and the real-time information can be integrated with your Ventsim model.

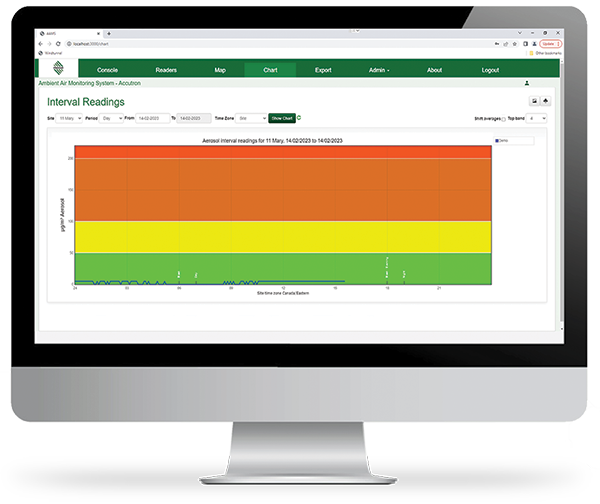

Live Visualization

View diesel particulate data through the AAMS dashboard software or through your current SCADA software.

Advanced Technology

The Pinssar unit uses light scattering photometry to sample particulate in the 0-800nm range with a calibrated range of 70-370nm.

Specifications

Communication Options

Over 200 industrial protocol options such as Modbus TCP

Network Capabilities

Ethernet

Optional: Wifi, Lte

Power In

110-240 VAC, 120W

Other options available on request

Enclosure

IP64 stainless steel

Particulate

Calibrated to diesel particulate matter <800nm

Pinssar Dashboard

The Pinssar Dashboard provides a live visualization of you data from every reader on site. The dashboard is an easy to use interface which records samples from your Pinssar DPM and displays it in a live graphical view. The data is compatible with your control system and can be used in all ventilation simulation software. Export data into charts, configure notifications and analyze historical data as well as internal diagnostics all from the Pinssar Dashboard.

Advanced Technology

Pinssar DPM uses advanced laser-light scattering photometry to measure diesel particulate matter in real time. The Pinssar unit samples particulate in the 0-800nm range with a calibrated range of 70-370nm. It is preset to take samples every 5 minutes but can range from 2 minutes to several hours. After each sample is taken the optical cell is flushed with filtered air. The Pinssar DPM also features automatic drift compensation on every sample.

Never Exceed DPM Limits

Pinssar DPM allows operations to protect workers from dangerous diesel exposure through management and controls. When placed in tunnels, underground mines, diesel engine workshops and confined spaces, the Pinssar DPM monitors diesel exhaust in real time to make sure operations aren’t exceeding occupational exposure limits. Continuous monitoring and correct ventilation ensures greater health and safety!

Get a Personalized Quote

Contact us for more information, product pricing and advice on the best solution for your application.