AccuAlert DPM

Personal diesel particulate monitor.

The AccuAlert DPM is a personal diesel particulate monitor that provides real-time readings of DPM concentrations. The personal monitor provides alarms for DPM concentrations and also features a filter cassette that allows users to simultaneously collect samples for NIOSH compliance testing.

- In-line concurrent filter samples for gravimetric analysis

- Internal flow compensated air sampling pump

- Choice of 1, 4, 10 or 60 second averaging/storage intervals

- Memory storage of up to 43,000 data points or 15 days

- Adjustable alarms alert workers for approaching threshold limits

Features

NIOSH Compliance Monitoring

Compatible with any pre-loaded 37 or 25mm filter cassette for NIOSH compliance testing.

Calibration Verification

Zero and span check the instrument calibration in the field. The AccuAlert DPM Sensor can easily be cleaned.

User selectable Alarms

Set concentration ranges and audible alarms to warn workers of approaching hazardous DPM levels. Set TWA, STEL, Max and Min levels.

Compact pErsonal dpm Monitor

The compact unit clips onto the workers belt for on-site monitoring and the small sensor is placed in the OSHA defined breathing zone.

Specifications

Connectivity

Micro USB

AccuAlert Windows driven software

Measurement

Diesel particulate matter

1.0 to 5.0 liters/minute sample flow rate (temperature, pressure & load compensated)

Calibration

Aerosol photometer SAE test dust standard

DPM particulate profile calibration

Cyclone

Standard GS3 (4.0 um)

SCC1.062 Triplex Cyclone (1.0um, 2.5um, 4.0um)

SCC0.695 Personal Sampling Cyclone (0.8um)

Weight

Instrument 508 g (1.14lbs)

Sensor 270g (0.6 lbs)

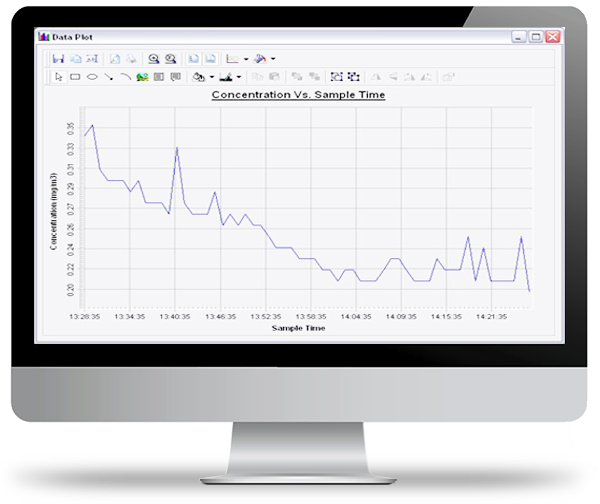

AccuAlert DPM Software

The AccuAlert DPM software logs reports and graphs making the AccuAlert an excellent survey tool for determining when workers are exposed to diesel contaminates. Store and analyze detailed sampled data. Create graphs and charts and export data to spreadsheet programs such as Excel.

NIOSH Compliance Testing

The AccuAlert DPM personal diesel particulate monitor uses traditional and real-time methods for monitoring DPM. Air is drawn by a vacuum pump through a 25mm or 37mm diameter membrane filter. These filters can be sent to the lab for NIOSH compliance testing.

As the air is drawn into the sensor, particles are detected once every second. DPM concentrations are instantly calculated and displayed on the units touch screen. This real-time data is stored for future analysis. If an event of elevated diesel particulate occurs, the lab results can be cross checked with the historical data from the device to pin point when/where the event happened.

Get a Personalized Quote

Contact us for more information, product pricing and advice on the best solution for your application.