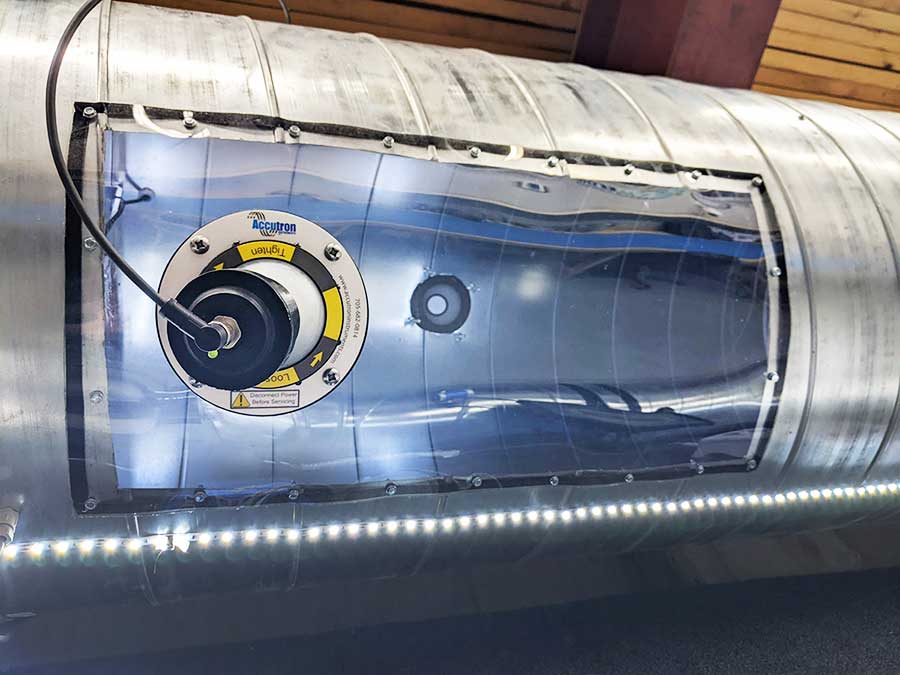

Wind Tunnel Test Chamber

Sensor Testing and calibration.

Accutron's wind tunnel test chamber is our facility for instrumentation testing, training and product demonstrations.

Accutron’s wind tunnel test chamber is an in-house testing facility were our sensors are tested and calibrated in an operational ventilation duct system. With our facility we are able to demonstrate products and carry out training either in-person or virtually. Our test chamber has the capability to remotely control and demonstrate products in a live environment.

Technology Test Bench

Technology

6 airflow monitoring systems, silica monitor, dust monitor, diesel particulate monitor, gas monitors, industrial display warning system, SCADA software, 2 louver PID controllers, interactive fan & louver and climate monitors.

Specifications

Our test chamber has a maximum velocity of 8m/s.

Referenced Airflow Elements

We reference a Dwyer hot wire anemometer, Trolex vortex flow sensor, and an NIST Certified Dwyer Vane anemometer for our airflow.

Consistent Calibration

We consistently calibrate and test each airflow system.

Fully remote controlled for virtual training.

Our facilities virtual training is carried out on an online platform that includes real time data, an interactive interface, high definition webcam and data graphing. Training can be conducted online by our trained Accutron staff with calibration certificates available. Join us in person or remotely to see how Accutron Instruments can improve mine air quality.

Want to learn more about our products?

See our instrumentation demonstrations for yourself! Contact us to set up a meeting.